+86-13363216781

Views: 29 Author: Site Editor Publish Time: 2025-12-10 Origin: Site

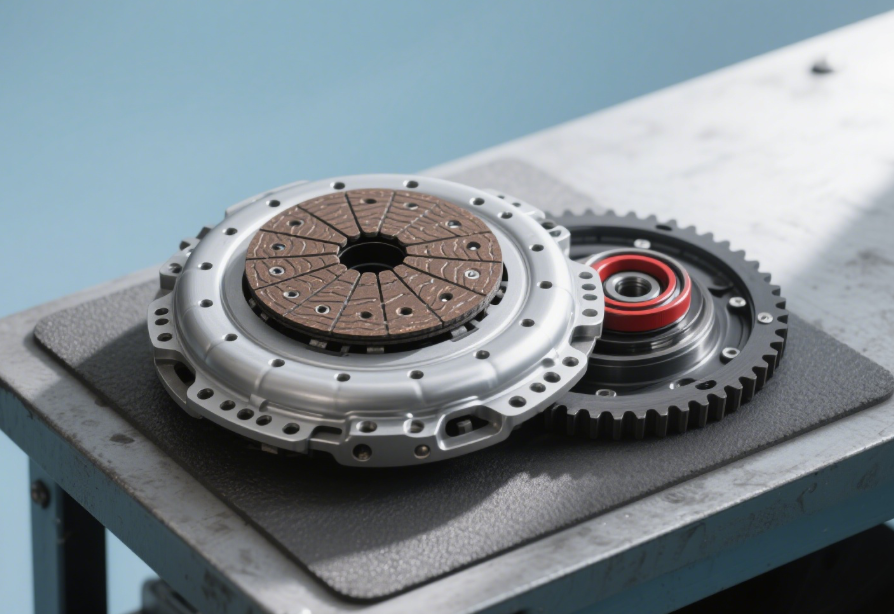

As a core friction component in the transmission system, clutch plates' wear and high-temperature resistance directly determine power transmission efficiency and service life. Especially in heavy-load commercial vehicles and high-power racing vehicles, clutch plates must withstand dozens of friction impacts per second and temperatures exceeding 500°C, placing stringent demands on production processes. This article will comprehensively analyze the key technologies for achieving wear and high-temperature resistance in clutch plates, from material formulation to molding process to surface treatment, revealing the process secrets behind their transformation from "ordinary parts" to "durable core."

The foundation of clutch plate performance lies in the friction material formulation. Through the precise blending of base material, reinforcement, and functional fillers, a balance of wear resistance and high-temperature resistance is achieved.

Metal-Based Base Material: Commercial vehicle clutch plates typically use metal powders such as iron, copper, and nickel as their base material (accounting for 50%-70%). Iron-based materials have a hardness of HV200-250 and excellent wear resistance. Adding 10%-15% copper powder improves thermal conductivity and prevents local overheating. The addition of 5%-8% nickel raises the material's heat resistance to over 800°C, making it suitable for heavy-load hill climbing.

Ceramic-based substrates: High-performance passenger vehicles often use ceramic fibers (such as alumina fibers) as substrates. They have a high-temperature resistance of up to 1200°C and a density only one-third that of metal. Adding 5%-10% silicon carbide particles can improve wear resistance by 40% while maintaining a stable coefficient of friction at 0.35-0.45.

Carbon fiber-reinforced substrates: Racing car clutch plates use carbon fiber as their backbone (30%-40%), leveraging its tensile strength (above 3000 MPa) and high-temperature resistance (long-term operating temperature of 300°C+) to create a high-strength structure. Combined with a resin binder, they achieve a balanced "rigidity-toughness" balance.

Wear-Resistant Fillers: Adding 10%-15% graphite or molybdenum disulfide utilizes its layered structure to achieve self-lubrication, reducing friction surface wear and noise. Micro-corundum powder (2%-5%) enhances surface hardness and is suitable for high-torque transmission applications.

Heat-Resistant Fillers: Titanium dioxide (5%-8%) and mica powder (3%-5%) reflect heat generated by friction and slow substrate aging. Zinc oxide (2%-4%) absorbs acidic gases generated during braking and prevents corrosion.

Friction Coefficient Regulator: Antimony sulfide (3%-6%) stabilizes the friction coefficient and prevents slippage at elevated temperatures. Iron oxide (5%-10%) forms an oxide film at high temperatures, protecting the substrate from damage.

Advanced molding processes are key to ensuring the full performance of the material. High temperature and high pressure transform the formulated material into a structurally stable friction layer.

Mixing Stage: Metal powder, reinforcing fiber, and filler are placed in a three-dimensional mixer in appropriate proportions. A binder (such as phenolic resin) is added and stirred for 2-4 hours to ensure uniform distribution (error ≤ 3%). Humidity must be strictly controlled (≤ 5%) during this stage to prevent powder clumping that could affect molding.

Pressing: The mixed material is placed into a mold and pressed under a pressure of 150-200 MPa to form a green body. Commercial vehicle clutch plates utilize a "step-by-step pressurization" process: pre-pressing at 50 MPa for 10 seconds, then gradually increasing the pressure to 200 MPa and holding for 30 seconds to reduce internal porosity (porosity is controlled within 5%).

Sintering and Curing: The green body is placed in a continuous sintering furnace and heated in stages under a protective gas (nitrogen) atmosphere: 200°C for binder removal, 600°C for preliminary sintering, and 850-950°C for 2-3 hours to metallurgically bond the metal particles. A gradient cooling process (≤100°C per hour) is used during the cooling phase to prevent cracking caused by thermal stress.

Prepreg Preparation: Carbon or ceramic fibers are placed in a resin bath (containing phenolic or epoxy resin), with a controlled resin content (30%-40%). After drying, they are cut into predetermined sizes to ensure consistent fiber orientation (improving fatigue resistance).

Lamination and Hot Pressing: Prepregs are alternately stacked with metal backing sheets (or core sheets) and placed in a hot press. Pressing is performed at 150-180°C and 10-15 MPa pressure for 30-60 minutes. Precise control of the temperature-pressure curve is achieved: the heating phase (5°C/minute) prevents rapid resin volatilization, while the holding phase ensures full resin curing and a dense structure.

Post-processing Grinding: After cooling, the friction surface is precision-grinded to ensure a flatness tolerance of ≤0.05mm and a roughness of Ra1.6-3.2μm. This not only improves contact with the pressure plate but also prevents premature wear caused by excessively rough surfaces.

Through surface modification and structural optimization, the clutch plate's wear and high-temperature resistance is further enhanced, extending its service life.

Plasma Spray Coating: A nickel-based alloy or ceramic coating clutch plate (0.1-0.3mm thick) is sprayed onto the friction surface. Using a plasma arc (temperatures exceeding 10,000°C), the coating forms a metallurgical bond with the substrate, increasing its hardness to HV300-400 and wear resistance by over 50%. It also blocks heat transfer to the core plate.

Chemical Vapor Deposition (CVD): The racing clutch plate uses CVD technology to deposit a diamond film (5-10μm thick). The friction coefficient is stable at 0.4-0.5 and there is no noticeable wear at 600°C, making it suitable for high-frequency use under extreme operating conditions.

Phosphating: The metal backing plate surface is phosphated to form a porous phosphate film (5-10μm thick), which enhances adhesion to the friction layer and prevents delamination at high temperatures.

Ventilation Groove Design: Radial or spiral ventilation grooves (0.5-1mm deep) are created on the friction layer surface to increase the heat dissipation area by over 30%, while quickly discharging friction debris and reducing abrasive wear.

Corrugated Core Plate: The stamped corrugated metal core plate absorbs 20% more impact energy than a flat plate, reducing fatigue wear caused by high-frequency vibrations and making it particularly suitable for the bumpy road conditions of commercial vehicles.

Gradient Structure Design: The friction layer adopts a gradient structure of "high wear resistance - medium cushioning - strong bonding" from the surface to the core plate. The surface layer contains 20% corundum particles to enhance wear resistance, the middle layer adds 10% elastic fiber to absorb impact, and the bottom layer adds 5% adhesive to ensure a secure bond with the core plate.

Strict testing procedures are key to verifying process effectiveness, and qualified products are screened by simulating extreme operating conditions.

Bench Wear Test: 100,000 friction cycles are conducted on a clutch test bench at 1500 rpm and 200 N·m of torque. Qualified products must exhibit wear ≤ 0.3 mm, with no visible cracks on the friction surface.

Road Simulation Test: 30,000 kilometers of comprehensive road testing (including urban congestion, high-speed cruising, and mountain climbing) using a real vehicle. Wear uniformity is required to be ≥ 90%, avoiding excessive localized wear.

Thermal Decay Test: The friction coefficient is tested every 50°C between 200°C and 600°C. The acceptance standard is a decay rate of ≤15% (e.g., a friction coefficient of 0.4 at 200°C must be ≥0.34 at 600°C).

High-Temperature Durability Test: The friction layer is maintained at 500°C for 10 hours. After cooling, the friction layer is inspected for bulging or cracking. Core plate deformation must be ≤0.1mm.

The wear and high-temperature resistance of clutch plates is the result of the synergistic effect of multiple steps, including material formulation, molding process, and surface treatment. In the future, with the integration of nanomaterials and 3D printing technology, clutch platemanufacturing will develop towards "customization" and "ultimate" development—precisely adjusting performance parameters to meet the needs of different vehicle models, truly achieving "on-demand manufacturing." For consumers, understanding these process details will not only help them better select suitable products, but also enable more scientific maintenance of the clutch system, extending its service life.To learn more information about brake system,you can visit our website:https://www.evfriction.com.Please contact us by +86-13363216781 or jessicabrakes12@gmail.com if you have any questions.